Solar Panel Installer Careers in the US: Training, Pay, and Flexible Schedules

Outline:

– The Market Momentum and Why It Matters

– Skills, Training, and a Day in the Life

– Pay, Benefits, and Advancement Paths

– Schedules, Lifestyle, and Work Settings

– Credentials, Safety, and Long‑Term Mobility

The Market Momentum and Why It Matters

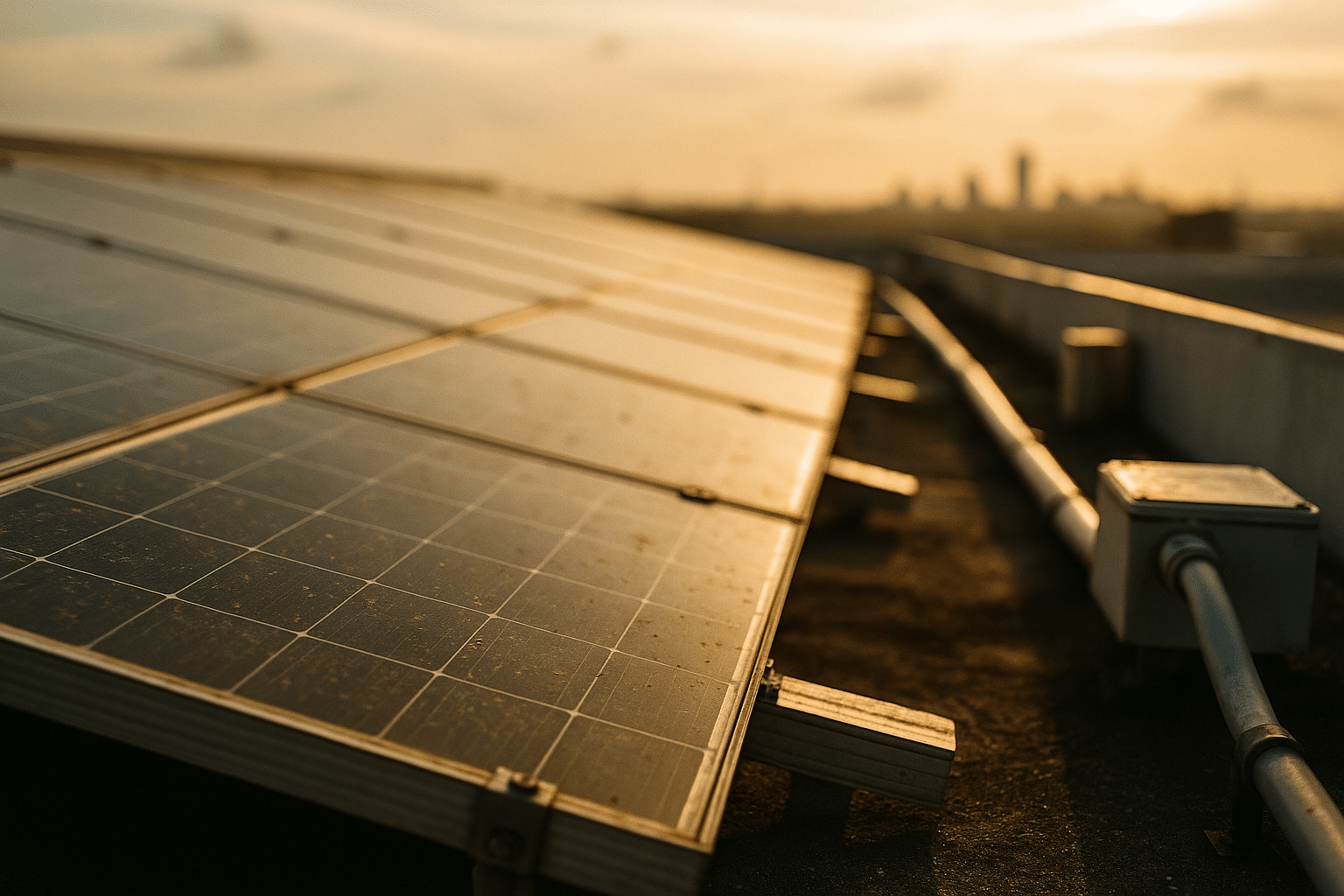

Across the country, rooftop and ground-mounted solar projects are being planned, permitted, and built at a pace that would have seemed ambitious a decade ago. Utility-scale fields stretch along rural roads, commercial rooftops turn unused space into productive assets, and homes host tidy arrays that quietly generate power during peak daylight hours. This momentum reflects persistent cost declines, wider access to financing, and policies that reward clean generation. In practical terms, it means steady demand for skilled hands that can measure, mount, wire, and commission systems safely and efficiently. Explore rewarding solar panel installer roles in the US.

Why does this trade matter right now? Electricity demand is poised to grow with data centers, electrified heating, and transportation, all while communities look to reduce emissions and improve resilience. Solar contributes by producing energy near where it’s used, lowering transmission strain and diversifying supply. For workers, that translates to consistent work across residential, commercial, and utility segments. Entry points exist for those new to construction, as well as for experienced electricians, roofers, and maintenance technicians seeking a new specialty. A typical crew blends these backgrounds: some members focus on layout and racking, others on wiring and testing, and others on documentation and quality control.

Consider the diversity of settings: coastal zones with salt-laden air, snowy mountain towns that require elevated arrays, and sunny plains where ground screws and piles anchor rows of modules. Each environment asks installers to adapt. That variety boosts employability, because you learn to navigate different roof materials, soils, wind loads, and permitting checklists. The work also supports local economies through year-round roles in operations and maintenance once projects are energized. While growth rates vary by state and county, many regions report double-digit installation increases year over year, with forecasts suggesting faster-than-average job expansion through the decade. For purpose-driven jobseekers, it’s an opportunity to pair climate impact with a hands-on trade that builds visible results, one racking rail and conductor at a time.

– Strong demand drivers: falling equipment costs, supportive policy, and rising electricity needs.

– Tangible community benefits: new tax base, local hiring, and more resilient power.

– Transferable skills: construction math, electrical fundamentals, and site safety habits.

Skills, Training, and a Day in the Life

Most installer days begin with a tailboard talk: reviewing tasks, hazards, and the plan of the day. Crews unload racking, verify layout lines, and set anchors before panels ever leave the pallet. Once the structure is square and plumb, modules are secured, conductors are routed, and connections are tested with a meter before the system is energized. Newcomers are typically paired with experienced leads who explain torque specs, grounding points, and cable management methods that stand up to weather. Join a growing clean-energy field with hands-on training.

Core capabilities break into a few buckets. Technical skills include safely using impact drivers, torque wrenches, and multimeters; reading one-line diagrams and plan sets; and recognizing wire types, connector ratings, and overcurrent protection. Construction skills include measuring accurately, aligning rows, and penetrating roofs without compromising weatherproofing. Professional habits—punctuality, clear communication, and documentation—keep projects on schedule and inspectors confident in the workmanship. Expect to learn staging and material flow as well: moving pallets to minimize carrying distance, pre-assembling roof hardware on the ground, and bundling conductors for clean drops.

Because solar sites differ, so does the rhythm of the day. Rooftops require fall protection and careful footwork around skylights and vents; ground sites demand trenching coordination and racking alignment over uneven terrain. Weather is a teacher: heat management, wind awareness when handling large panels, and moisture control around electrical enclosures. Training is available through community programs, employer-run apprenticeships, and short courses covering electrical basics and safety. Many crews create a learning ladder that moves a new hire from material handling to racking assembly, then to module install and basic wiring under supervision, followed by commissioning support and quality checks.

– Typical tasks: site layout, racking assembly, module placement, wiring, labeling, and testing.

– Useful tools: tape measure, level, impact driver, torque wrench, multimeter, conduit bender.

– Safety essentials: fall protection, ladder management, lockout/tagout procedures, and PPE.

Pay, Benefits, and Advancement Paths

Compensation in solar installation reflects regional cost of living, project complexity, and certifications. Entry-level hires often start at hourly rates comparable to other construction trades, with increases as they demonstrate speed, accuracy, and safe habits. Many employers review pay at 30-, 60-, and 90-day milestones to recognize rapid skill growth. Overtime can be common during peak build seasons, which can raise take-home pay when projects must meet commissioning dates. Competitive pay and benefits for solar techs.

Benefits packages vary, yet frequently include health coverage, paid time off, and retirement contributions, along with extras like per diem for travel crews, lodging when working out of town, mileage reimbursement, and tool stipends. Some teams add training allowances or exam fee reimbursements to encourage continuous learning. Career ladders are well-defined: helper or laborer, installer, senior installer, crew lead, and foreman. Beyond the field, experienced technicians move into warehouse coordination, quality assurance, safety, design drafting, project management, site inspection, or sales estimating. That breadth means you can shift roles as your interests evolve, without leaving the industry.

Several variables influence earnings over time. Residential work may offer quicker job turnover and customer tips; commercial sites often feature larger crews and more structured schedules; utility-scale projects can provide consistent months-long assignments with travel compensation. Specialized skills—string inverter commissioning, data logger setup, or troubleshooting arc-fault trips—can justify higher pay as you become the person crews call when problems arise. Soft skills matter too: leading morning briefings, mentoring new hires, and coordinating with inspectors all signal readiness for higher responsibility and wage tiers.

– Pay drivers: state and city wage norms, project size, certifications, and overtime availability.

– Common benefits: health insurance, PTO, retirement match, travel per diem, and training stipends.

– Advancement routes: crew lead, foreman, QA/QC, safety, design, project management, or sales.

Schedules, Lifestyle, and Work Settings

One of the trade’s strengths is its adaptability to different lifestyles. Some crews operate four 10-hour days to capitalize on daylight, freeing a weekday for personal appointments. Others prefer five 8-hour days for routine. Travel crews may work two weeks on and one week off, concentrating hours to finish remote builds. Local residential teams often keep you home for dinner most nights. In all cases, success comes from managing energy, hydration, and rest, because field work demands focus and safe attention to detail. Flexible schedules for solar site work.

Work settings range widely. On residential rooftops, you’ll meet varied roof pitches, tile or metal surfaces, and local weather patterns that affect handling and staging. Commercial flat roofs emphasize layout precision over large spans, equipment pad planning, and safe material hoisting. Ground-mount sites involve racking alignment over long distances and coordination with excavators and electricians for trenching and conduit runs. Seasonality plays a role: sunny stretches accelerate productivity, while rain or snow days may shift work to warehouse prep, inventory, or training refreshers.

Time management and communication keep schedules smooth. Crews that review the next day’s material needs avoid morning delays; leads who brief homeowners or facility managers build trust and unlock easy site access; technicians who log photos and test results reduce rework. When weather interrupts, experienced teams pivot to tasks that can proceed safely, such as electrical terminations under cover or labeling. Over time, you’ll learn to read forecasts not just for precipitation, but for wind gusts that complicate panel handling and for heat that calls for more frequent breaks.

– Common schedule models: 5x8s, 4x10s, compressed travel rotations, and weekend make-up days.

– Typical environments: pitched roofs, flat commercial roofs, and open-field racking lines.

– Productivity habits: stage materials smartly, pre-assemble components, and close out quality checks daily.

Credentials, Safety, and Long‑Term Mobility

Credentials signal readiness for responsibility and higher pay tiers. Many states allow entry into solar installation without an electrical license, provided a licensed professional performs final connections and oversight; other jurisdictions require more direct licensing for DC and AC work. Either way, employers value candidates who document training hours, master electrical basics, and maintain a clean safety record. Industry-standard safety courses cover fall protection, ladder use, basic electrical safety, trenching awareness, and hazard communication. Path to certification with on-the-job training.

A practical roadmap begins with foundational knowledge: DC vs. AC, series vs. parallel wiring, voltage drop considerations, and conductor sizing concepts. From there, build proficiency with tools—especially torque control and meter use—and with installation sequencing that protects the roof membrane or ground conditions. Seek out short courses or employer classes that culminate in written and hands-on assessments; these not only add to your resume but also build confidence in real site conditions. As you gain hours, you can pursue nationally recognized solar credentials and, where applicable, step into supervised electrical tasks that expand your scope.

Long-term mobility in this field is strong because solar interlocks with storage, EV charging, and energy management. Technicians who can commission monitoring gateways, interpret performance data, and troubleshoot issues like ground faults or communication timeouts are valuable across segments. The same applies to those who read permits, prepare inspection packets, and interface respectfully with authorities. Over time, you can tilt your career toward operations and maintenance, construction leadership, design and estimating, or site auditing—each drawing on the same bedrock of safety and electrical knowledge.

– Step-by-step growth: pre-hire basics, trainee installer, independent installer, crew lead, and beyond.

– Safety habits to cement: tie-off discipline, tool tethering, correct PPE, and energized work boundaries.

– Documentation to keep: training certificates, hours logged, inspection sign-offs, and test results.